Zeus

#176

Thread Starter

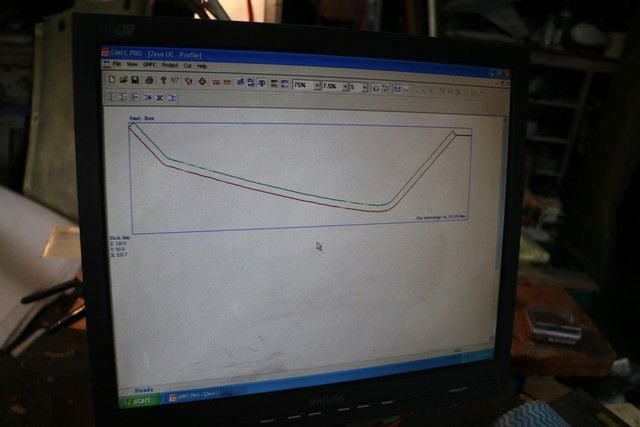

I've been able to have a rough balance up and the CofG is going to be pretty much where I designed it. So I can now make the UC legs. Here is the profile on the CNC foam cutting PC.

Cutting the extruded foam block.

Mylar Vac bagged onto it with PU glue.

#178

Thread Starter

UC mold ready with dams in place.

20 layers of UNI carbon and 2 of 45 degree bias cloth on the outside.

In the bag with 2 layers of breather soaker. Quite a bit of resin coming out so I changed out the soaker after this. I am using slow hardener and it is now in the electric blanket. The heat should reduce the viscosity of the resin and allow it to be soaked up before it goes off.

#179

Thread Starter

Made a spinner back plate from 6mm ali plate. It still needs the spokes cut.

Fit is OK. I will be painting it white with red flash on the front. Better get on with that prop.

#184

Thread Starter

Cheers Jim. I just count myself luck that I have the time to do this stuff. When my next contract turns up it will all stop.

Out of the press after over 40 hours.

Untrimmed weight and it has lost 16gms since taking it out of the press 3 hours ago.

Next one in the press. It is nice to be able to check how straight the trailing edge is. I torque the nuts down by feel more at the root than the tip. I think it must be possible to work out exact amounts of torque to allow for the different area each bar is compressing.

Out of the press after over 40 hours.

Untrimmed weight and it has lost 16gms since taking it out of the press 3 hours ago.

Next one in the press. It is nice to be able to check how straight the trailing edge is. I torque the nuts down by feel more at the root than the tip. I think it must be possible to work out exact amounts of torque to allow for the different area each bar is compressing.

#187

Thread Starter

Second wing panel is out of the press an is 10gms lighter at 258 gms. Had another balance up checked my measurements and drilled the wing tube holes in the fuselage. Had a preliminary weigh up and I'm pretty confidant it will make weight. I might even be able to fit a Tcan. My muffler build is not going well, so i am reviewing my options on that.

#188

Second wing panel is out of the press an is 10gms lighter at 258 gms. Had another balance up checked my measurements and drilled the wing tube holes in the fuselage. Had a preliminary weigh up and I'm pretty confidant it will make weight. I might even be able to fit a Tcan. My muffler build is not going well, so i am reviewing my options on that.

#189

Loving this build, exceptional skills. Its great to see how composite work is done in such detail.

I also cant wait to see how it goes with a da50!

Had a few 50cc extras etc with da50's and most would pull out of a hover at half throttle, weighing about 17-18lb. The prop you showed that you're replicating could you make that a 3 blade?

Also Im wondering if 8"+ pitch would be too fast?

Anyway it will be fun finding out!

Great work.

Dan

I also cant wait to see how it goes with a da50!

Had a few 50cc extras etc with da50's and most would pull out of a hover at half throttle, weighing about 17-18lb. The prop you showed that you're replicating could you make that a 3 blade?

Also Im wondering if 8"+ pitch would be too fast?

Anyway it will be fun finding out!

Great work.

Dan

#190

Thread Starter

Cheers Dan and Graham. Well the DA 50 can certainly afford to be de-rated. A 3 blade prop would be good but I didn't want the complexity of building one that is why I went for the wide 2 blade. This is what is known as blade solidity or the ratio of blade area to swept area and this wide blade should be fairly similar to a normal 3 blade. As for pitch, I suppose it is really about down line braking but it's all a bit of an unknown due to the high volume/drag of this fuselage although I have done a fairly slippery wing. As you say it will be fun finding out.

#191

My Feedback: (2)

Join Date: Jan 2002

Location: Ossining,

NY

Posts: 630

Likes: 0

Received 0 Likes

on

0 Posts

Ch

Next one in the press. It is nice to be able to check how straight the trailing edge is. I torque the nuts down by feel more at the root than the tip. I think it must be possible to work out exact amounts of torque to allow for the different area each bar is compressing.

Next one in the press. It is nice to be able to check how straight the trailing edge is. I torque the nuts down by feel more at the root than the tip. I think it must be possible to work out exact amounts of torque to allow for the different area each bar is compressing.

Dick Hanson used a similar system using automotive valve springs. The springs had a known rate so by measuring the compression he knew the force exerted.

#192

Thread Starter

Yes I see Dick is still posting and he mentioned recently that the press was his preferred method. I can see how the spring method would work. I do prefer the vacuum bag and I am well set up to do it including a back up compressor and vacuum tank with Festo vacuum switch. The reason I used the press was the PVA glue needing to air dry. I will be going back to bagging for my next project as it will have no honey combing and a full paint finish.

#193

Thread Starter

Made titanium axles screws and washers for the UC. Still a bit left for nuts

Titanium machines nicely just hard on the cutting tools.

Good savings to be had

#200

Thread Starter

I'm OK with this as it is a time/money/skill thing. We are still seeing some beautiful models popping up pretty regularly (such as yours). I'm liking what I'm seeing in the Classic Pattern scene. I have a couple of projects in the pipeline there.